Food Processing Line

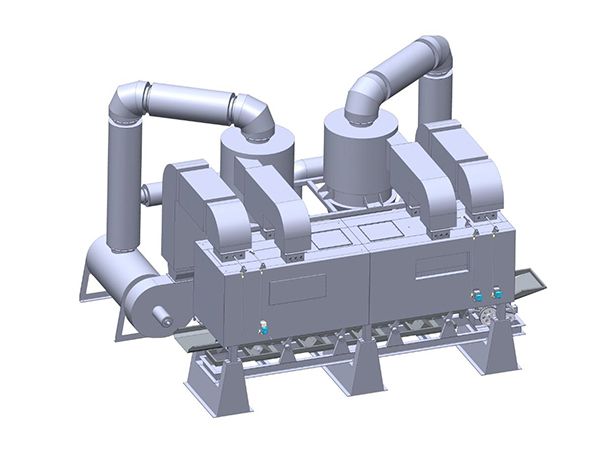

Industrial Dryers & Baking Ovens

We offer customized drying solutions for a variety of products, such as, low temperature drying for fortified rice/pellets, medium temperature drying for puff snacks/cereals/Kurkure, high temperature baking for corn flakes, and oil-free pellet frying.

Our industrial dryer and baking ovens are featured by robust structure made of high quality stainless steel materials, and a reasonable hot air circulation system that is both highly efficient and energy saving.

Our machinery design department and technology department are comprised of experienced engineers and food production equipment designers. LIGHT food processing machinery, animal food machinery, food extruders, etc. are used widely in the field of food processing, and we also provide customers with total food-production and processing solutions. We take pride in our ability to provide newer, better equipment to our customers to handle their ever changing needs.

Are you planning on making something tasty and visually attractive?

We can provide solutions tailored to your specific needs.

Contact Us